Wood joinery is an age-old craft that involves connecting pieces of wood together to create strong and beautiful structures. From simple butt joints to complex dovetails, understanding the basics of wood joinery is essential for any aspiring woodworker. In this article, we will explore the fundamental techniques and terminology of wood joinery, providing a comprehensive guide for mastering this timeless art form. Whether you’re a seasoned carpenter or a novice DIY-er, join us as we delve into the fascinating world of wood joinery.

Understanding Wood Joinery Techniques

Wood joinery techniques are essential skills for any woodworker looking to create strong and beautiful pieces of furniture or woodworking projects. Understanding how different wood joinery techniques work can help you to choose the right method for each project, ensuring a professional finish every time.

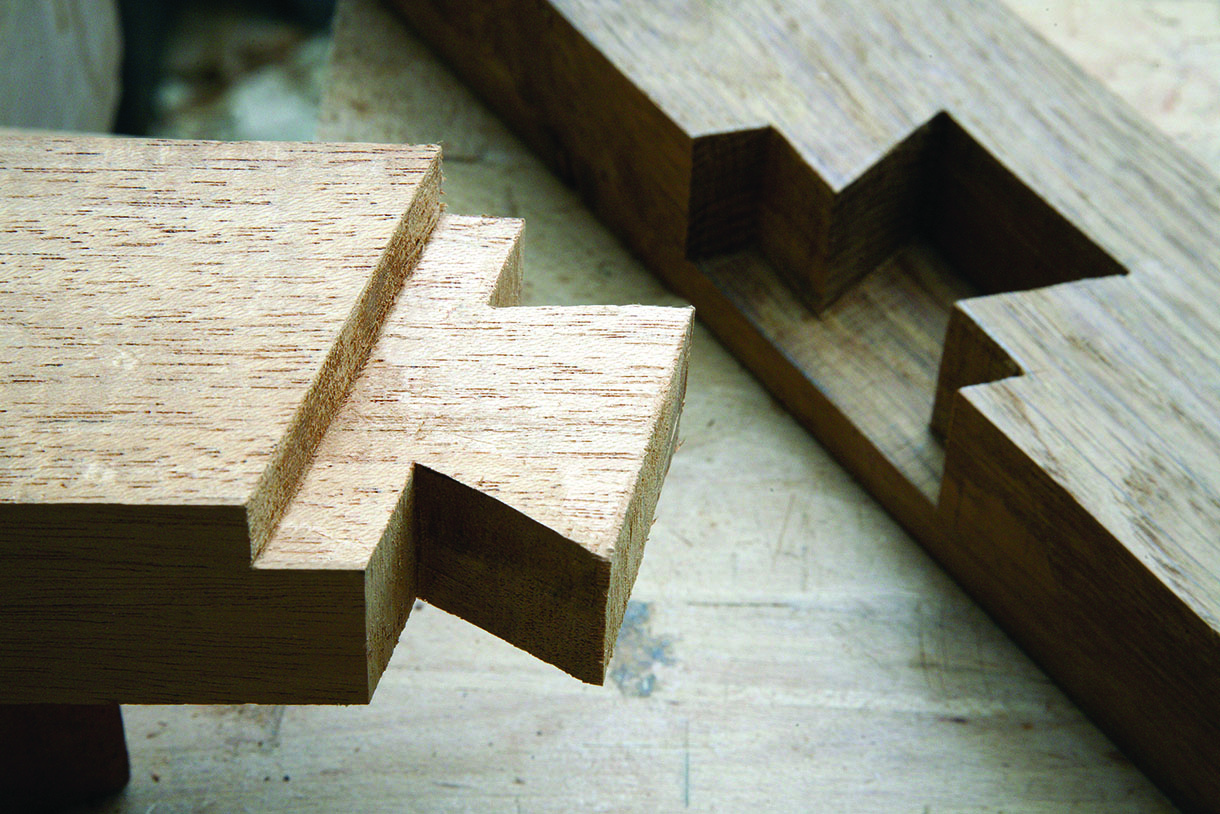

One of the most common wood joinery techniques is the dovetail joint, known for its strength and durability. This joint consists of interlocking pins and tails that prevent the pieces from being pulled apart. Another popular technique is the mortise and tenon joint, which involves a protruding tenon fitting into a cavity called a mortise.

For those looking for a simple and versatile wood joinery technique, the butt joint is a popular choice. This technique involves joining two pieces of wood by simply butting them together. While not as strong as other techniques, the butt joint is easy to create and can be reinforced with nails or screws for added stability.

Different Types of Wood Joints and Their Uses

There are various types of wood joints that are commonly used in woodworking, each with its own unique characteristics and uses. Understanding these different types of joints can help you choose the right one for your project and ensure a strong and durable finished product.

Some of the most common types of wood joints include:

- Butt joint: This simple joint is made by joining two pieces of wood at their ends. It is commonly used in cabinet making and other simple woodworking projects.

- Dovetail joint: This joint is known for its strength and decorative appearance. It is often used in furniture making, especially for drawers.

- Mortise and tenon joint: This traditional joint consists of a tenon on one piece of wood fitting into a mortise on another piece. It is commonly used in furniture construction and other woodworking projects that require a strong, durable joint.

Essential Tools and Materials for Wood Joinery

When it comes to wood joinery, having the right tools and materials on hand is essential for creating strong and beautiful wooden pieces. Whether you are a seasoned carpenter or just starting out, having a well-stocked workshop is key to successful projects.

Some of the essential tools for wood joinery include:

- Clamps: Clamps are used to secure pieces of wood together while the adhesive or fasteners dry. They come in various sizes and types, such as bar clamps, spring clamps, and pipe clamps.

- Chisels: Chisels are needed for making precise cuts and shaping wood joints. They come in different shapes and sizes, such as bench chisels, mortise chisels, and dovetail chisels.

- Saws: Saws are essential for cutting wood to size and shaping joints. Common types of saws used in wood joinery include handsaws, backsaws, and dovetail saws.

| Tool | Function |

|---|---|

| Clamps | Secure pieces of wood together |

| Chisels | Make precise cuts and shape wood joints |

| Saws | Cut wood to size and shape joints |

In addition to tools, having the right materials is also crucial for successful wood joinery. Some of the essential materials include:

- Wood Glue: Wood glue is used to bond pieces of wood together. It comes in various types, such as PVA glue, epoxy, and polyurethane glue.

- Dowels: Dowels are wooden pegs used to reinforce joints and add strength to woodworking projects. They come in different diameters and lengths.

- Screws and Nails: Screws and nails are commonly used fasteners in woodworking. They come in various sizes and types, such as wood screws, finishing nails, and brad nails.

Tips for Achieving Strong and Durable Wood Joints

When it comes to creating strong and durable wood joints, there are a few key tips to keep in mind. By following these guidelines, you can ensure that your woodworking projects are not only beautiful but also built to last.

One important factor to consider when joining wood pieces together is the type of joint you use. Different joints have varying levels of strength and durability, so it’s essential to choose the right one for your project. Some common types of wood joints include:

- Butt joints: These are the simplest type of joint, where two wood pieces are simply butted together.

- Dovetail joints: These are interlocking joints that are known for their strength and durability.

- Mortise and tenon joints: This type of joint consists of a mortise hole in one piece of wood that fits a tenon projection on the other piece.

Another key tip for achieving strong and durable wood joints is to ensure that your wood pieces are properly prepared before joining them together. This includes planing, sanding, and ensuring that the surfaces are flat and smooth. Proper preparation will help create a tight and secure joint that will last for years to come.

As we conclude our exploration of the basics of wood joinery, we hope you have gained a deeper understanding of this essential skill in woodworking. Remember, whether you are crafting a simple picture frame or constructing a complex piece of furniture, the quality of your joinery will ultimately determine the strength and longevity of your project. So, practice your joinery techniques, experiment with different joints, and continue to hone your skills to unlock the true potential of woodworking. With dedication and patience, you can master the art of wood joinery and create beautiful, functional pieces that will stand the test of time. Happy woodworking!